Avoid over sizing the boiler

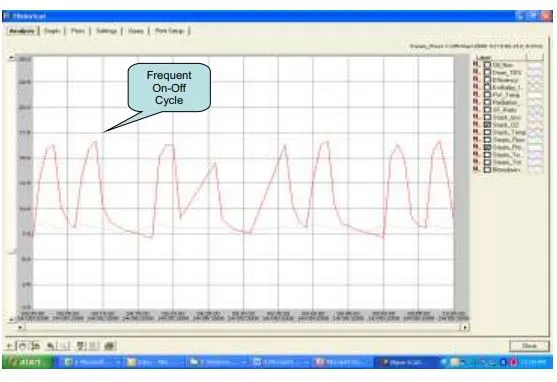

Avoid over sizing the boiler. Over sizing leads to recurring on-off cycles in a boiler which lowers boiler efficiency.

An oversized boiler helps meet process heating demands quickly and shuts off till heat is required in the process again. This is referred to as boiler “short cycling”.

Most boilers operate on the cross limiting control scheme, where the air flow increases before the fuel flow increases and it decreases after the fuel flow decreases. Thus, during switch on and switch off more heat is carried away with the air to the stack, reducing the over all efficiency.

This also causes the heat in the combustion chamber to be carried away by the air purge, which results in greater stack loss and thereby reduced boiler efficiency.

Hence, oversizing boilers must be avoided. In case of existing establishments with oversized boilers, by analysing the plant load pattern, it is possible to make adjustments to the boiler so as to minimise the losses.

Illustration:The illustration below shows increased stack loss through variation of excess air as against the steam pressure in the boiler. As seen the oxygen content in the stack peaks when boiler cuts in and cuts out.