Reducing steam consumption and OPEX at a leading fragrance specialty chemicals manufacturer in South Asia

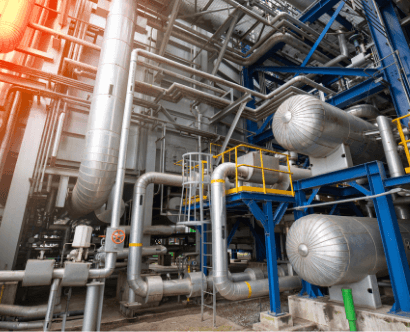

The plant was experiencing severe steam-related production bottlenecks, with inadequate steam pressure in two blocks disrupting the productivity of distillation columns. Along with this, a higher Specific Steam Consumption (SSC) vis-a-vis plant’s energy consumption norms for each of their products was contributing to the inefficiencies.

Forbes Marshall offered an end-to-end solution comprising audit, design consultancy, product supply, technical supervision and quantification of savings. Our solution eliminated production bottlenecks, improved feed water temperature and significantly reduced the specific steam consumption across their product range.

What to read next

Products

Associated Services

Process Optimization

Improving Uptime