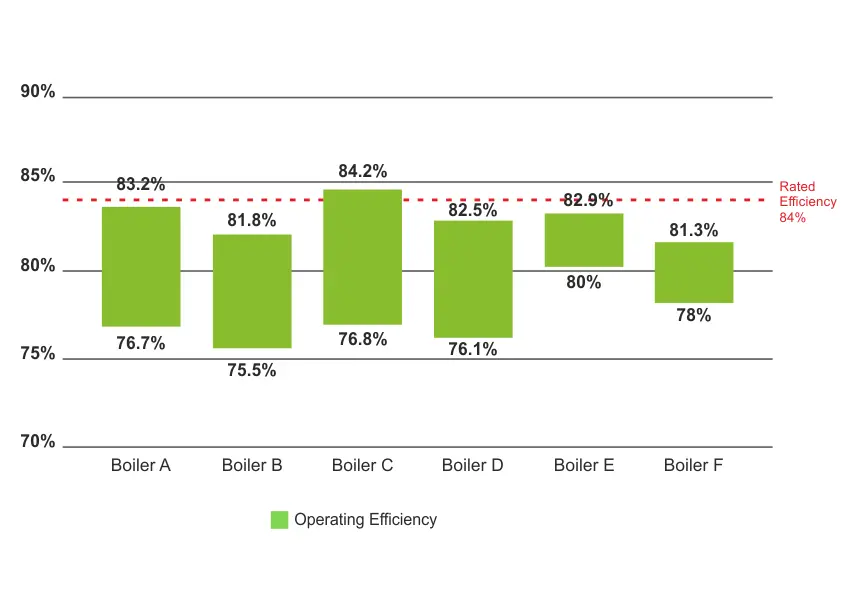

On average, boiler performance can be improved by 4-10% and sustained.

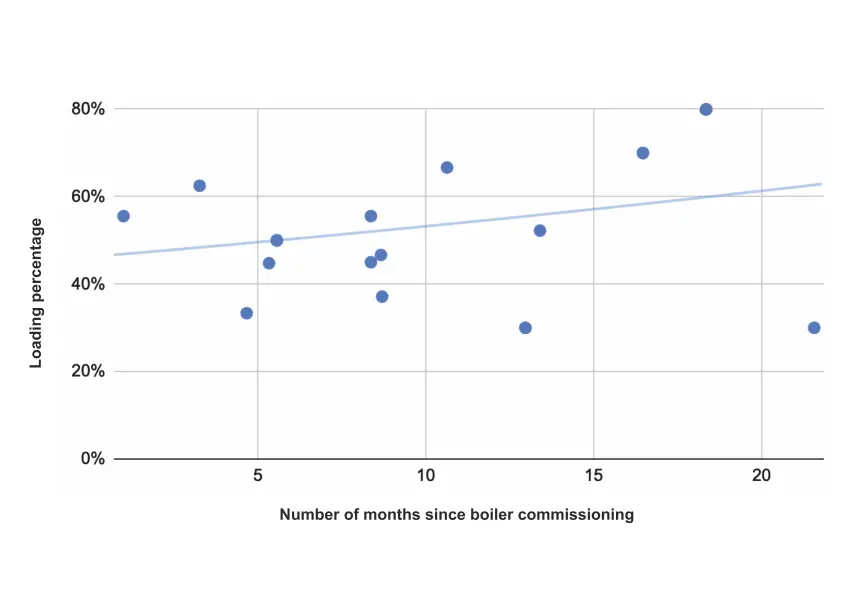

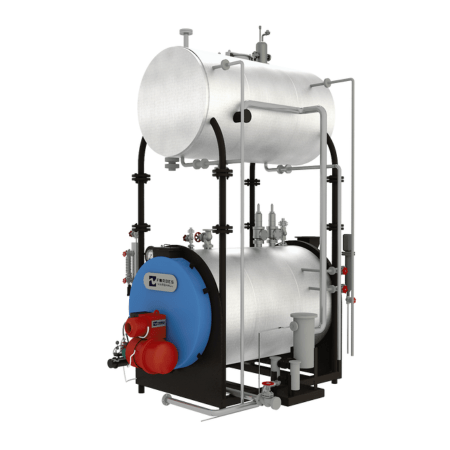

Boiler performance fluctuates hourly, irrespective of boiler type or age of the equipment. The efficiency of new boilers can also be impacted by overall plant conditions. On average, new boilers tend to operate at 51% load within the first year of operation. Such part load operations can increase fuel consumption by 4-10%. Additionally, uptime is impacted by various factors including maintenance practices, operating loads, fuel and water quality, inappropriate settings, poor combustion, condensate recovery and infrequent monitoring.

We derive real-time, tangible solutions by monitoring key parameters, to enhance standard operating procedures (SOPs) and provide actionable insights. This delivers better overall efficiencies: resulting in sustaining >95% uptime, a reduction in not only the cost of steam, but also reducing impact on the environment.

Key parameters we monitor

Efficiency

Steam: Fuel ratio

Steam flow/ Boiler load

Steam pressure

O₂ % in fuel gas

Stack temperature

Blowdown TDS (Total Dissolved Solids)

Feedwater temperature

Furnace draft (*applicable for solid fuel fired boilers)

We provide actionable insights

Delivering Benefits

Our

footprint

across services

footprint

across services

500

Plants

1200

Assets

7500

Parameters