Conventional Trapping Station vs. Advanced Mainline Steam Trapping

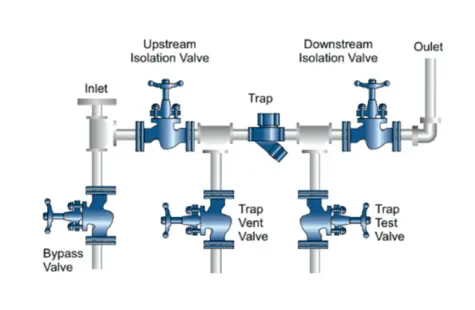

Thermodynamic steam traps are ideal for condensate evacuation from steam distribution lines due to benefits like lower OPEX, suitability for high and low pressures systems. A conventional mainline steam trapping station consists accessories like an inlet isolation and outlet isolation valve, a strainer, a trap bypass valve, a trap depressurization valve and a trap test valve, combined with piping into one cumbersome station making it difficult to install and maintain.

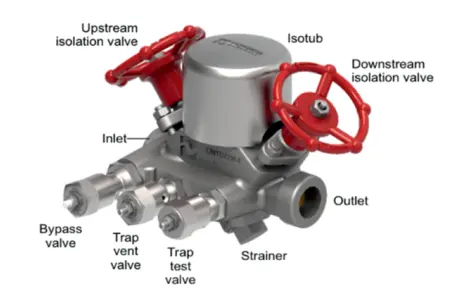

Meanwhile, an advanced steam trapping solution consists of a single steam trap module forged into one single body, making it easy to install, operate and maintain. CMTD or a Compact Module Thermodynamic Steam Trap is an ideal example of one such advanced trapping solution.

Table : Comparison of conventional steam pipeline trapping station against an advanced mainline steam trapping solution

| Conventional Steam Trapping Station | Advanced Mainline Steam Trapping Solution |

|---|---|

|

|

| Approx. 750mm assembly length and weighing over 14 kgs | Compact and lightweight – 190mm assembly length and weighing about 6kgs |

| Has 16 components with 5 valves requiring on-site fabrication and welding (15 weld joints); ~ 4 hours to install and commission | Only one component with 5 integral piston valves; installation time of ~30 minutes |

| Shutdown / safe isolation not possible, hampering online / in-line maintenance as traditional valves are prone to leakages and seizing up | Integral class VI bypass and isolation valves enable safe isolation for easy and safe online/ in-line maintenance |

| Trap needs to be replaced in case of damage to the seat | Replaceable seat and disc |

| Intermittent, noisy and scattered discharge of hot condensate causing erosion of surface onto which the condensate is discharged | Inbuilt diffuser enables reduction in noise level and gentle discharge of condensate for open to atmosphere applications thus ensuring safety |

| Cumbersome to maintain due to welded joints | Quick and easy to maintain |

| Potential steam leaks through inline leakages, glands and weld joints | Zero leakage |