Brewery

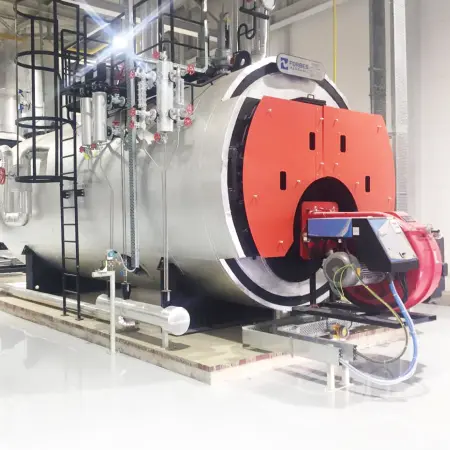

Bottle Washer

Cleaning and sanitisation of bottles before filling prevents product

contamination. Bottles are passed through a sequence of immersion or soak tanks with temperatures starting from about 60°C in the initial tank and reaching a maximum of 80°C in the final tank.

common operational issues include inconsistent temperature, high start-up times, condensate contamination and lower recovery, reduced bottle washer speed and high steam consumption.

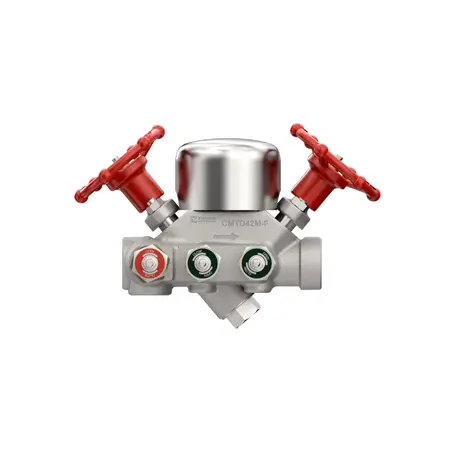

Our Solution:

The holistic solution from Forbes

Marshall encompasses