Use Steam at the Lowest Possible Pressure for Indirect Heating

Using steam at the lowest possible pressure for indirect heat exchange reduces the steam requirement for that process and thus the fuel consumption. This is because latent heat of steam increases with a decrease in steam pressure.

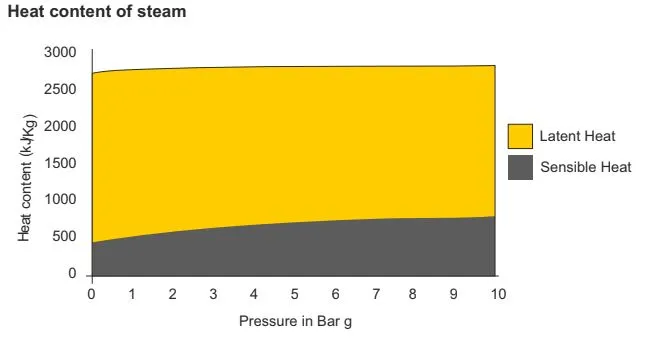

‘Latent heat’ forms a major portion of the energy content of steam. This latent heat is used in indirect heating applications in a process. The condensate that comes out of the plant equipment contains a portion of heat termed as ‘sensible heat’.

As seen from the illustration below, latent heat in steam increases as steam pressure decreases, i.e. more usable heat for the process and thus lower steam consumption, translating into lower fuel bills.

Illustration: Comparison of Latent Heat vs. Sensible Heat in Steam at Varying Pressures

Example: Steam generated and distributed at 9 bar g would, on condensation, release 480.9 Kcal/kg of heat. Reducing the pressure to 3 bar g would result in an extra 28.47 Kcal/kg of heat being available.