More Paper, Better Paper, Less Steam

In the paper industry, there’s a significant gap between the best and worst-performing plants, offering huge potential for improvement. Inefficient operations can waste as much as 37% of fuel consumption and 26% of steam consumption.

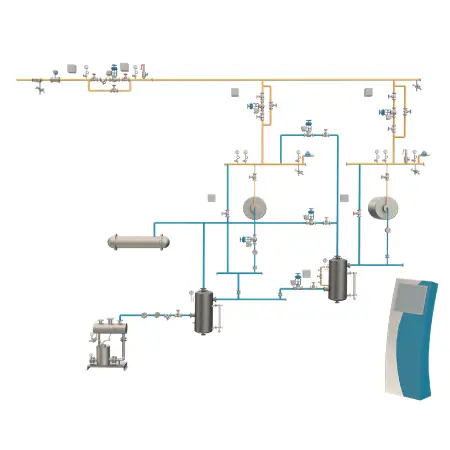

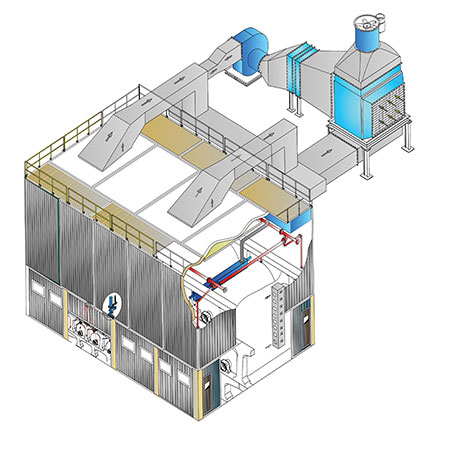

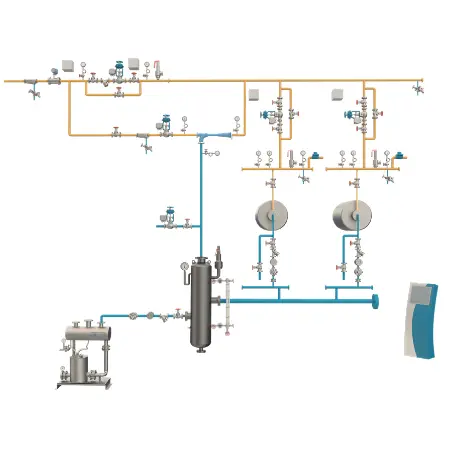

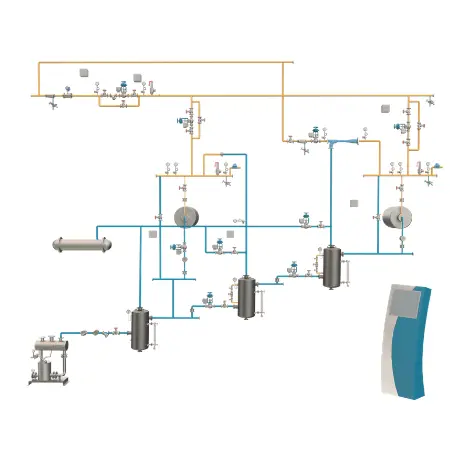

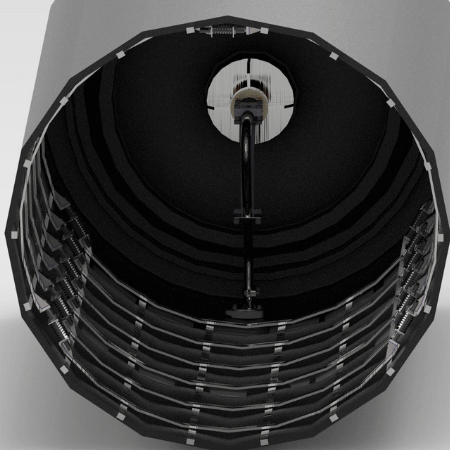

Forbes Marshall partners with pulp and paper manufacturers globally to close this gap. We provide customised steam and condensate solutions, and process control systems that deliver proven results. Our engineered systems include thermocompressor based paper systems, steam trap based paper systems and cascade based paper systems along with stationary syphons and rotary joints, advanced steam trapping, condensate and flash steam recovery systems. These solutions are designed to reduce specific steam consumption, achieve maximum condensate recovery, and improve product quality by stopping energy waste and optimising overall efficiency.

Forbes Marshall surveys and plant audits help you identify bottlenecks in your plant and process, helping troubleshoot and identify savings opportunities.

Our advanced digital services for paper machine systems help sustain performance. Our platform provides real-time monitoring of key performance indicators like Specific Steam Consumption (SSC) and Condensate Recovery Factor (CRF). By tracking production data, steam usage, and paper breaks, we provide the insights needed to continuously optimise process energy and maintain peak performance.