Install startup traps in the steam distribution system

Situations may arise when steam supply to either the whole plant or certain sections/production blocks is shut off. In such cases, the distribution piping can cool down to ambient temperatures (depending on the duration for which steam is shut-off). When steam is once again admitted to such pipe lines, it will rapidly condense. It is imperative to evacuate this condensate from the pipelines quickly to avoid water hammer. Condensate logging in the steam pipelines will also prolong start up time as it will take longer for the pipelines to attain the operating temperature. Typically, during startup, many plants resort to manually opening the steam trap bypass valves. If plant personnel inadvertently miss opening the bypass valves it can result in damage to the pipeline or pipeline accessories. Consequently, if they forget to shut off the bypass valves it can lead to significant loss of steam.

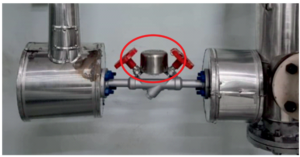

Startup traps are devices that automate this process, eliminating dependence on manual intervention to open / close bypass valves during startup.

Startup traps operate on the thermostatic principle. When the steam supply is shut-off the residual condensate in the pipeline becomes sub-cooled. At this time the startup traps open and release the condensate.

Startup traps operate on the thermostatic principle. When the steam supply is shut-off the residual condensate in the pipeline becomes sub-cooled. At this time the startup traps open and release the condensate.

When the pipelines are once again charged with steam, the startup trap evacuates condensate, until the condensate temperature reaches 90°C. Once the condensate temperature exceeds 90°C, the startup trap automatically closes.

Provide thermodynamic steam traps with diffusers :

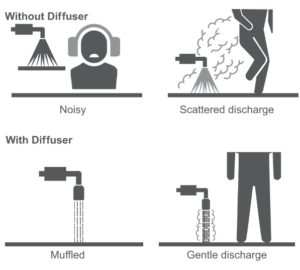

Thermodynamic traps discharge large quantities of hot condensate intermittently. When these traps are left open to discharge to the

atmosphere they pose a safety hazard as hot condensate is discharged as a blast. A diffuser is a compact unit designed to be fitted at the outlet of the thermodynamic steam trap discharging to the atmosphere. It dampens the velocity of condensate discharge, thereby eliminating the blast of condensate making it safer for plant personnel in the vicinity. The diffuser also addresses other problems associated with the blast discharge from thermodynamic traps like noise and erosion of the ground.

Provide thermodynamic steam traps with an Isotub :

The operation of a thermodynamic steam trap is governed by the flash steam generated within the trap. Flash steam accumulates on

top of the trap disc, applying pressure and causing the disc to move downward, sealing the trap outlet. As this flash steam cools and condenses, the downward pressure exerted on the disc diminishes, allowing condensate pressure to lift the disc, thereby opening the trap outlet. When thermodynamic steam traps are exposed to extremely low ambient temperatures or rain, rapid condensation of the accumulated flash steam on the disc leads to more frequent opening and closing of the trap. This increase in the cycles of operation shortens its lifespan, resulting in premature failure. Additionally, it also leads to live steam loss.

An Isotub is a protective cap installed on top of the thermodynamic steam trap which isolates it from the surrounding environmental conditions.