Recovering flash steam

Flash steam is a valuable source of energy, accounting for almost 50% of the total energy in condensate. Its recovery and utilisation is crucial in enhancing the efficiency of the steam system.

Before initiating the recovery of flash steam, it is important to assess the amount of flash steam that can be potentially recovered.

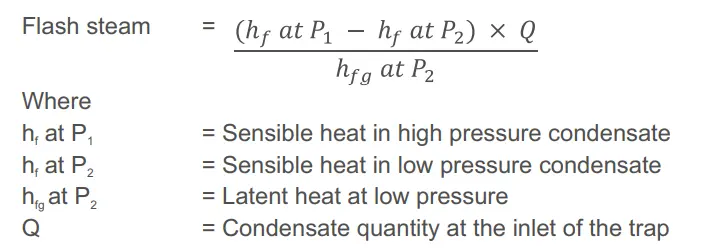

Flash steam can be calculated using the following formula:

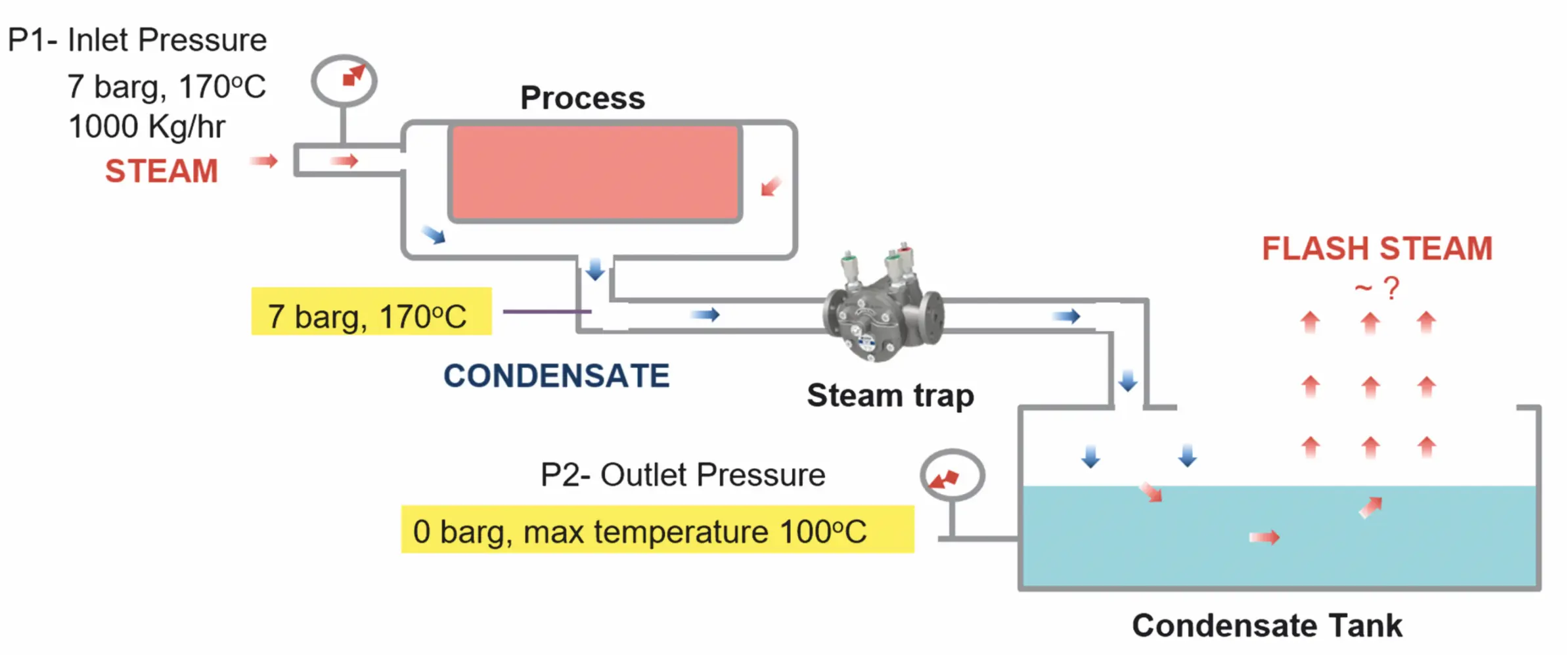

In the above illustration, steam at 7barg is supplied to a process equipment. The condensate is collected in an open tank.

h f at P₁ = Sensible heat in high pressure condensate = 170Kcal f 1

h f at P₂ = Sensible heat in low pressure condensate = 100Kcal f 2

h fg at P₂ = Latent heat at low pressure = 540Kcal

Q = Condensate quantity at the inlet of the trap = 1,000kg/hr

Using the above formula,

Flash steam = (170 – 100) x 1,000 / 540

= 129.6 kilograms/hour

Therefore when condensate at 7barg is flashed at atmospheric pressure 129.6 kilograms/hour of flash steam will be generated, leaving behind 870 kilograms/hour of condensate.

There are two options for utilising flash steam: returning it to the boiler feed water tank or using it within a process application.

Recovering flash steam and returning it to the boiler feed water tank increases the temperature of feed water, reducing the boiler fuel consumption.

Alternatively, flash steam can be used locally within the process area in a low pressure application. Doing so reduces the consumption of live steam in the process. However, the feasibility of this option depends on the availability of a suitable low pressure application within the plant.