Rectification and Sustenance

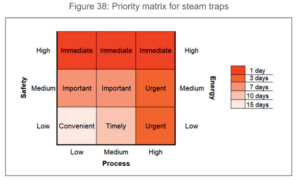

Rectification can involve a number of actions including correcting installation issues, cleaning, replacing of internals (repair) or replacement of the complete trap. Rectification could also involve addressing the valves or components of the steam trap module or design related issues that are impacting the performance of the steam trap. While rectification is being carried out it is also important to identify the root cause of failure and address the same to prevent recurrence. Creating a priority matrix as illustrated below can not only aid in resource allocation, ensuring that limited resources are allocated to address the most critical aspects first but also help optimize inventory management.

Maintaining an inventory of spares and new traps can significantly expedite the rectification process as it reduces delays associated with waiting for spares / traps to be made available. While determining the quantity of spares / new traps to be maintained in the inventory factors like criticality of the trap, failure rates, lead time for procurement should be considered.

Personnel training is pivotal, ensuring the team responsible for trap management is well-versed in inspection and testing techniques, familiar with various trap types used in the facility.

Regular inspections and periodic maintenance is important to improve and sustain the performance of the steam trap population.