In compressed air systems, every excess 1 bar of pressure leads to a 7% increase in electricity costs. On average, we can reduce energy consumption by 15-25%.

Compressed air is used for powering pneumatic tools, automation systems, and material handling equipment, and contributes to about 30% of electricity costs incurred by industries. Issues in the air compressors and the associated compressed air network often go unnoticed, hindering productivity and impacting operational costs.

The most common problem faced is leaks in the network which can amount to up to 40% of compressed air costs. Inadequate piping design or blockages in the air distribution network can cause pressure drops, reducing the effectiveness of pneumatic tools and equipment. Artificial demand due to inefficiently designed systems, incorrectly sized compressors, pressure drops or unregulated end use is another significant challenge, contributing to about 10-15% of the energy losses in a compressed air network.

With the percentage proportion of energy consumption by compressed air applications in an industry ranging between 10-40%, we can help reduce the energy consumption by 15-25%, by improving the energy efficiency of compressed air systems.

Key parameters we monitor

Free Air Delivery

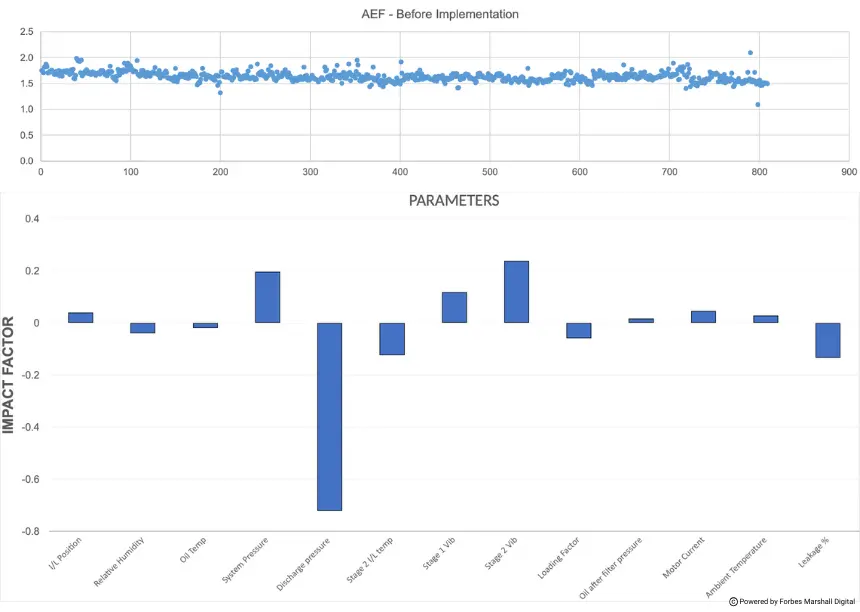

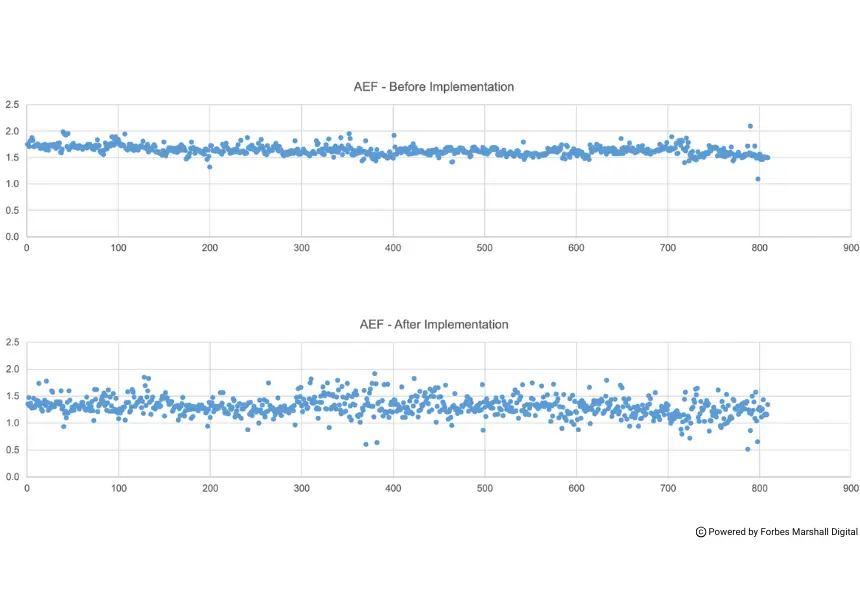

Air Energy Factor (Actual SEC/Ideal SEC)

Specific Energy Consumption (kWH/SCFM)

Artificial Demand

Compressor Discharge Pressure

TDS of Cooling Water

Leakage % (inclusive of drain losses)

Stage 1 & 2 Vibration

Pressure variations and Demand Analysis across the end user

We provide actionable insights

Delivering Benefits

Our

footprint

across services

footprint

across services

500

Plants

1200

Assets

7500

Parameters